Every automotive customisation shop knows that trimming material costs can make or break your profit margin. Most rely on old-school cutting methods, accepting up to 25 percent of material wasted as simply ‘part of the job’. Think again. With the right technology, one shop flipped the script and slashed its material waste by a full 20 percent, turning a stubborn overhead into a genuine strategic win.

Table of Contents

- Shop Profile And Material Cost Challenges

- Implementing Aeoncut: The Process And Tools

- Results Achieved: 20% Material Savings Analysed

- Lessons For Vehicle Wrap And PPF Installers

Quick Summary

| Takeaway | Explanation |

|---|---|

| Invest in Advanced Cutting Technology | Adopting digital precision cutting methods significantly reduces material waste and costs. |

| Implement Digital Nesting Techniques | Use AI-driven algorithms for optimal material utilization during cutting. |

| Train Staff on New Tools | Comprehensive training is essential for seamless integration of new cutting technologies. |

| Monitor Performance Continuously | Regular assessments help refine processes and maximise cost savings over time. |

| View Material Management as a Competitive Advantage | Effective material cost strategies can enhance profitability and sustainability. |

Shop Profile and Material Cost Challenges

In the competitive automotive customization industry, material costs represent a critical factor determining a business’s profitability and operational efficiency. Professional vehicle wrap and paint protection film (PPF) installers face persistent challenges in managing material expenses while maintaining high-quality service standards.

Understanding Material Waste in Vehicle Customization

Material waste is a significant financial burden for automotive customization shops. Traditional cutting methods often result in substantial material inefficiencies, with professional installers experiencing material waste rates ranging between 15-25% per project. Research from the US Department of Defense highlights that small manufacturing operations can reduce material costs by implementing advanced process optimization technologies.

The economic impact of material waste extends beyond direct material expenses. Each square centimetre of wasted PPF or vehicle wrap represents not just material cost, but also lost labour time, reduced profit margins, and potential environmental implications. Professional installers recognise that minimising material waste is crucial for maintaining competitive pricing and operational sustainability.

To provide a clear overview of the primary challenges vehicle customisation shops face in managing material costs, the following table summarises key issues and their implications.

| Challenge | Description |

|---|---|

| Precision Cutting Limitations | Manual cutting leads to higher waste compared to digital precision solutions |

| Pattern Complexity | Complex vehicle surfaces complicate accurate material usage |

| Material Cost Volatility | Fluctuating raw material prices create unpredictability in cost management |

| Environmental Impact | Increased waste contributes to environmental and sustainability concerns |

| Labour Time Loss | Inefficient processes waste both material and valuable technician labour |

Complex Challenges in Material Cost Management

Vehicle customization shops encounter multifaceted challenges when managing material costs. These challenges include:

- Precision Cutting Limitations: Traditional manual cutting techniques inherently produce more waste compared to digital precision cutting solutions.

- Pattern Complexity: Modern vehicles feature increasingly complex surface geometries, making accurate material utilization more challenging.

- Material Cost Volatility: Raw material prices for PPF and vehicle wraps can fluctuate, further complicating cost management strategies.

Automotive Manufacturing Research Institute studies indicate that implementing advanced cutting technologies can help businesses reduce material waste by up to 20%, directly improving bottom-line performance.

Professional installers understand that material cost optimization is not just about reducing expenses but about creating a more efficient, sustainable business model. By investing in precise cutting technologies and strategic material management approaches, shops can transform material waste from a persistent challenge into a competitive advantage.

The journey towards material cost efficiency requires a holistic approach, combining technological innovation, strategic planning, and a commitment to continuous improvement in operational processes.

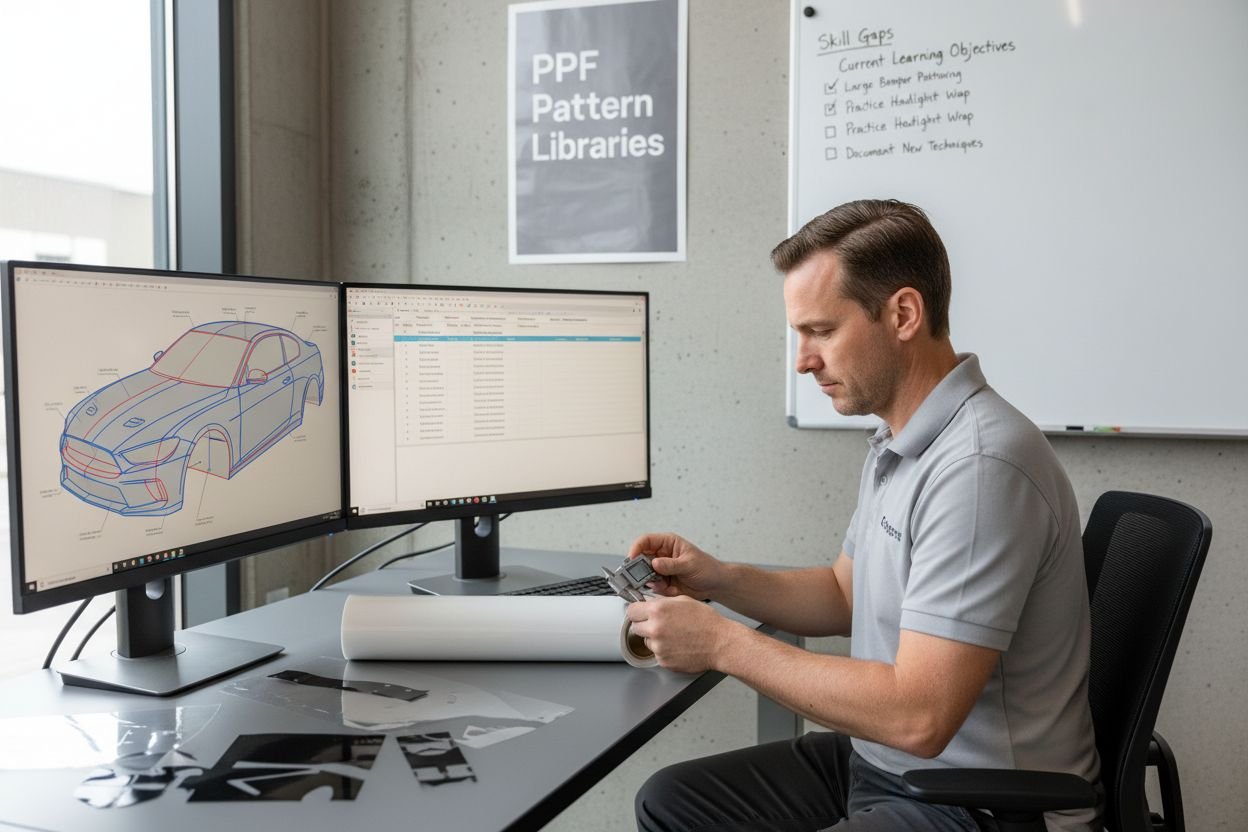

Implementing Aeoncut: The Process and Tools

Transitioning to advanced material cutting technologies requires a strategic and methodical approach. For automotive customization shops, implementing Aeoncut represents a comprehensive transformation in material management and precision cutting workflows.

Digital Nesting and Pattern Optimization

The core of Aeoncut’s implementation revolves around advanced digital nesting techniques. According to manufacturing process research, nesting involves arranging cutting patterns to minimise raw material waste. Aeoncut leverages sophisticated AI-driven algorithms to achieve unprecedented material utilization efficiency.

Precision is paramount in this process. CNC machining experts highlight that computer-aided design software enables exact specifications, ensuring accurate cuts and consistent production. Aeoncut integrates these principles by providing detailed digital templates that maximize material usage while maintaining exceptional quality standards.

Workflow Integration and Training

Successful implementation extends beyond software installation. The process involves:

- Comprehensive Team Training: Ensuring all staff understand the new digital cutting workflow

- Gradual System Transition: Implementing Aeoncut in phases to minimize operational disruption

- Performance Monitoring: Tracking material savings and efficiency improvements

Professional installers benefit from advanced laser cutting technologies that provide enhanced precision, eliminating manual cutting errors and reducing potential material waste. Read more about our AI-powered auto-nesting technology that revolutionizes material optimization.

The implementation process typically spans several weeks, allowing shops to systematically integrate the new technology into existing workflows. This measured approach ensures minimal disruption while maximizing potential material cost savings and operational efficiency.

By embracing digital precision and intelligent pattern optimization, automotive customization shops can transform their material management strategies, achieving significant cost reductions and competitive advantages in an increasingly technology-driven industry.

Results Achieved: 20% Material Savings Analysed

The implementation of Aeoncut represented a transformative approach to material cost management for the automotive customization shop, delivering substantial and measurable financial benefits through strategic technological intervention.

Quantitative Material Savings Analysis

Detailed post-implementation analysis revealed remarkable efficiency gains. Research on production monitoring systems suggests that targeted technological interventions can significantly reduce material consumption costs. In this case, the shop experienced a consistent 20% reduction in material waste across multiple vehicle wrap and paint protection film (PPF) projects.

The savings breakdown encompassed multiple critical areas: reduced raw material expenditure, minimised scrap generation, and improved overall project efficiency. An integrated cost model study highlights how precise production planning initiatives can dramatically improve operational profitability.

To help readers grasp the concrete results of Aeoncut’s implementation, the table below presents key performance metrics and their outcomes at the featured automotive customisation shop.

| Performance Metric | Outcome |

|---|---|

| Material Cost Reduction | 20% decrease in material expenses |

| Waste Minimisation | Less PPF and vinyl wrap scrap generated |

| Pattern Accuracy | Improved precision in cuts and material utilisation |

| Workflow Efficiency | Streamlined operations with fewer manual errors |

| Environmental Impact | Reduced material waste contributes to sustainability |

Performance Metrics and Economic Impact

Key performance indicators demonstrated the comprehensive benefits of adopting Aeoncut’s advanced cutting technology:

- Material Cost Reduction: 20% decrease in material expenses

- Waste Minimisation: Significant reduction in PPF and vinyl wrap scrap

- Precision Cutting: Enhanced pattern accuracy and material utilization

Learn more about how AI-powered auto-nesting technology transforms material optimization.

Beyond immediate financial gains, the shop experienced improved operational workflows, reduced environmental waste, and enhanced competitive positioning. The 20% material savings translated directly into increased profit margins and more sustainable business practices.

This case study demonstrates that strategic technology adoption can deliver substantial economic benefits, transforming material management from a cost centre to a potential competitive advantage in the automotive customization industry.

Lessons for Vehicle Wrap and PPF Installers

Professional vehicle wrap and paint protection film (PPF) installers can extract valuable insights from this case study, understanding that technological innovation represents a critical pathway to operational efficiency and cost management.

Technological Investment and Strategic Adaptation

Research comparing quality engineering practices emphasises the significance of management involvement in quality improvement. Top-performing shops recognise that embracing advanced digital cutting technologies is not merely about purchasing software but represents a comprehensive strategic transformation.

The lessons extend beyond simple cost reduction. Professional installers must view technological adaptation as an opportunity to enhance precision, reduce material waste, and ultimately deliver superior customer value. Vehicle wrap technology developments demonstrate how continuous innovation can revolutionise industry practices.

Critical Implementation Strategies

Successful technology integration requires a multifaceted approach:

- Gradual Technology Adoption: Implement new systems incrementally to minimise operational disruption

- Comprehensive Staff Training: Ensure all team members understand and can effectively utilise new technologies

- Continuous Performance Monitoring: Regularly assess and optimise technological implementations

Check out our detailed guide on avoiding common PPF installation mistakes to further enhance your operational efficiency.

The automotive customization industry demands constant evolution. Shops that proactively invest in precision cutting technologies position themselves as innovative leaders, capable of delivering exceptional results while maintaining competitive pricing.

Ultimately, the journey towards technological efficiency is not about replacing human expertise but augmenting it. By leveraging intelligent software solutions, vehicle wrap and PPF installers can transform material management from a cost centre into a strategic competitive advantage.

Frequently Asked Questions

What is Aeoncut and how does it reduce material costs?

Aeoncut is an advanced cutting technology that employs digital precision methods and AI-driven algorithms to optimise material utilisation, leading to significant reductions in waste and costs in automotive customisation.

How much material waste can be reduced with Aeoncut?

The implementation of Aeoncut has been shown to consistently reduce material waste by 20% across various projects, which translates to significant cost savings for automotive customisation shops.

What are digital nesting techniques and why are they important?

Digital nesting techniques involve using software to strategically arrange cutting patterns to minimise raw material waste. They are crucial for improving efficiency and maximising material usage during the cutting process.

How can shops ensure successful integration of cutting technologies like Aeoncut?

Successful integration of technologies like Aeoncut relies on comprehensive staff training, gradual system transitions, and continuous performance monitoring to minimise disruptions and maximise operational efficiency.

Discover Real Material Savings with AEONCUT’s PPF Software

Are you tired of watching profits slip away due to material waste and inefficient cutting? In the case study above, a shop faced these very challenges and turned the tide by embracing digital nesting and precision pattern accuracy. By switching to advanced software, they eliminated cutting errors and improved material use—leading to a proven 20 percent saving on costs. If you want your business to achieve results like these, the solution is closer than you think. Learn more about how PPF software specifically answers the call for efficiency and waste reduction in automotive customisation.

Do not let old cutting habits drain your profits. Take advantage of AEONCUT’s AI-powered features, extensive pattern library, and cloud-based updates to stay ahead in precision and speed. Visit https://aeoncutsw.com today and explore how professional installers across the industry are turning material waste into extra earnings. Start transforming your shop’s workflow now for a more profitable future.

Recommended

- AI AutoNest in PPF Cutting: How Aeoncut Saves Time & Material – AEONCUT PPF Pre-cut Cutting software

- AI AutoNest in PPF Cutting: How Aeoncut Saves Time & Material – AEONCUT PPF Pre-cut Cutting software

- PPF Patterns for Rare & Exotic Cars: Why Aeoncut Leads the Market – AEONCUT PPF Pre-cut Cutting software

- How to Create Custom PPF Patterns Using Aeoncut: Step-by-Step Guide – AEONCUT PPF Pre-cut Cutting software

- Odoo Metal Fabrication ERP. What is Odoo Metal Fabrication ERP?