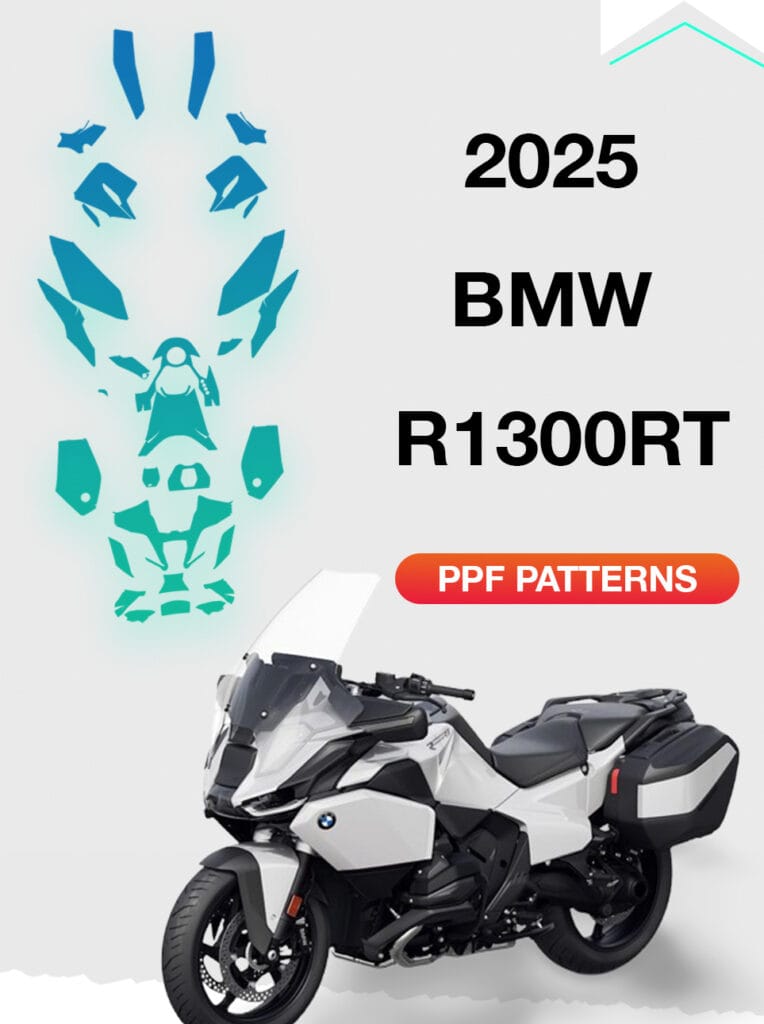

Exclusive Release: 2025 BMW R1300RT PPF Precut Patterns Now Available with Aeoncut

#image_titleMotorcycle enthusiasts and professional PPF installers, this is big news!

Aeoncut has just released precut paint protection film (PPF) patterns for the 2025 BMW R1300RT – one of the most iconic touring motorcycles in the world.

With this update, installers can now provide riders with perfect precision, superior coverage, and long-lasting protection without the risks of manual cutting.

- ✅ Weekly Updates

- ✅ Precision Patterns

- ✅ Advanced Software

Table of Contents

- Why 2025 BMW R1300RT Matters

- Introducing Aeoncut for Motorcycle PPF

- Benefits for Installers

- How Aeoncut Improves Efficiency

- Video Demonstration

- Frequently Asked Questions

Why 2025 BMW R1300RT Matters

The BMW R1300RT is an iconic choice for long-distance touring riders. Its premium design, advanced aerodynamics, and elegant curves make it a standout in the motorcycle world. But these same complex curves also make manual film cutting extremely difficult and wasteful.

Introducing Aeoncut for motorcycles PPF

Aeoncut’s precut software takes away the complexity by providing ready-to-install PPF templates designed specifically for motorcycles. Our engineers carefully map each panel of the 2025 R1300RT to ensure seamless protection.

- Accurate fit for every panel

- Reduced installation time

- Millimetre-perfect precision

- Optimized material usage

Benefits for Installers

By using Aeoncut, PPF shops can:

- Save up to 40% on wasted film compared to manual cutting

- Install faster, improving shop throughput

- Deliver consistency across every job

- Reduce training time for new installers

How Aeoncut Improves Efficiency

Aeoncut is not just about patterns; it’s about automation and AI-driven optimization. With auto-nesting and advanced design algorithms, every sheet of film is utilized to the maximum.

| Aspect | Manual Cutting | Aeoncut |

|---|---|---|

| Precision | Inconsistent | AI-driven accuracy |

| Material Waste | Up to 40% | Reduced by 40% |

| Time Required | High | 35% faster |

| Consistency | Variable | Guaranteed fit |

Video Demonstration

We are adding exclusive video demonstrations to show how Aeoncut simplifies the installation process for the 2025 BMW R1300RT. Videos will highlight:

- Pattern alignment

- Cutting precision

- Step-by-step installation workflow

👉 Subscribe to our YouTube Channel for updates.

Frequently Asked Questions

What are the main advantages of using Aeoncut over manual cutting methods?

Aeoncut offers significant benefits, including a 40% reduction in material waste, 35% decrease in installation time, and improved pattern precision by 25%.

How does Aeoncut improve cutting accuracy compared to traditional methods?

Aeoncut uses AI-driven algorithms for millimetre-perfect pattern generation and real-time dimensional analysis, ensuring precision every time.

Can Aeoncut help reduce the environmental impact of automotive film installation?

Yes, Aeoncut’s intelligent auto-nesting technology optimises material usage, leading to significant reductions in waste and supporting sustainability.

What kind of training is required for technicians to use Aeoncut effectively?

Aeoncut simplifies the cutting process, reducing training time. With its user-friendly interface, technicians can quickly learn to achieve high-quality installations.

Ready to transform your workflow? Visit Aeoncut Official Website and start your free trial today!