Precision matters when every millimetre of Paint Protection Film counts. Professional installers and detailing business owners know that flawless coverage and minimal waste are vital, especially when working with advanced polymer films engineered for physical impact resistance. Choosing the right cutting software directly affects both efficiency and the quality of vehicle protection applications. This guide highlights how modern solutions can help you achieve consistent, high-grade results while maximising material usage.

Table of Contents

- Defining Coating and Paint Protection Film

- Types and Applications in Vehicle Protection

- How Coatings and PPF Differ Technically

- Performance, Durability, and Maintenance Requirements

- Cost, Efficiency, and Choosing the Right Solution

Key Takeaways

| Point | Details |

|---|---|

| Protection Strategies | Paint Protection Film (PPF) provides superior physical protection, while coatings enhance aesthetics and chemical resistance. |

| Durability Considerations | PPF typically lasts longer and requires less maintenance than traditional coatings. |

| Cost Versus Value | Although PPF has a higher initial cost, its long-term benefits justify the investment for many clients. |

| Application Methods | Installation methods differ significantly, with PPF being pre-cut for direct application and coatings requiring precise application conditions. |

Defining Coating and Paint Protection Film

Coatings and Paint Protection Film (PPF) represent sophisticated automotive surface protection technologies designed to shield vehicle paintwork from environmental damage and wear. While these terms are often used interchangeably, they represent distinctly different protective strategies with unique characteristics and applications.

Paint Protection Film is a transparent, self-healing thermoplastic polyurethane layer specifically engineered to protect vehicle surfaces against mechanical and chemical damage. Constructed from advanced polymeric materials, PPF offers remarkable resilience against road debris, stone chips, insect impacts, and minor abrasions. Modern PPF technologies incorporate innovative features like self-healing topcoats that can automatically repair minor scratches and UV inhibitors preventing film yellowing or degradation.

Conversely, automotive coating represents a liquid-applied protective treatment typically composed of ceramic, polymer, or glass-based compounds. These coatings create a thin, transparent layer that chemically bonds with the vehicle’s paintwork, providing hydrophobic properties, enhanced gloss, and moderate protection against environmental contaminants. Unlike PPF, coatings are significantly thinner and primarily offer surface enhancement rather than comprehensive physical impact protection.

Below is a side-by-side comparison of key features of Paint Protection Film (PPF) and automotive coatings:

| Attribute | Paint Protection Film (PPF) | Automotive Coating |

|---|---|---|

| Material Type | Thermoplastic polyurethane | Ceramic, polymer, or glass |

| Thickness | Relatively thick (100-200 μm) | Very thin (1-5 μm) |

| Protection Focus | Physical impact and abrasion | Chemical resistance, gloss |

| Self-Healing Capability | Available in advanced films | Absent in standard coatings |

| Application Method | Pre-cut film installation | Liquid spray or wipe-on |

| Typical Longevity | 5-10 years (premium) | 2-5 years (with care) |

Pro Tip: When selecting between PPF and coating, consider your specific workshop requirements, client expectations, and the level of protection desired for different vehicle types and usage scenarios.

Types and Applications in Vehicle Protection

Vehicle protection technologies encompass a diverse range of applications designed to safeguard automotive surfaces from environmental degradation, mechanical damage, and aesthetic wear. These protective strategies range from comprehensive film coverings to specialised corrosion-resistant coating systems that defend against multiple potential damage mechanisms.

Protective Coating Types can be categorised into three primary classifications based on their protective mechanisms. Barrier coatings create a physical shield preventing direct environmental contact with the vehicle’s surface. Inhibitive coatings integrate chemical compounds that actively suppress corrosion processes, while sacrificial coatings utilise metallic layers like zinc or aluminium to provide electrolytic protection by deliberately corroding before the underlying metal substrate.

For quick reference, here are common protective coating types and their main purposes:

| Coating Type | Main Function | Example Application |

|---|---|---|

| Barrier | Prevents direct environmental contact | Protects against moisture |

| Inhibitive | Suppresses corrosion chemically | Shields metal from rust formation |

| Sacrificial | Corrodes before substrate to protect | Galvanised chassis protection |

Different vehicle protection applications demand specific coating technologies tailored to unique environmental challenges. Automotive manufacturers and detailing professionals typically select protection methods based on factors including expected usage conditions, vehicle type, budget constraints, and desired longevity. Performance vehicles might require more advanced multilayered protection systems, whereas standard passenger cars could benefit from more economical yet effective coating solutions.

Pro Tip: Always conduct a comprehensive assessment of the specific vehicle environment and usage patterns before recommending or applying any protective coating technology.

How Coatings and PPF Differ Technically

Vehicle protection technologies exhibit profound technical distinctions that significantly impact their performance and application. Technical composition fundamentally separates paint protection film (PPF) from traditional coating systems, creating unique characteristics that determine their effectiveness in automotive surface preservation.

PPF represents a pre-fabricated, elastic thermoplastic material engineered with sophisticated polymer technologies. Unlike liquid coatings applied through spraying or dipping, PPF arrives as a precisely cut, ready-to-install transparent film. Its molecular structure enables remarkable self-healing properties, allowing minor scratches to disappear automatically—a capability absent in standard coating formulations. The film’s elasticity provides superior impact absorption, protecting vehicle surfaces from stone chips, road debris, and mechanical abrasions with unprecedented resilience.

Coatings, conversely, function as liquid-applied protective layers that chemically bond with the vehicle’s paintwork. These systems create thin, uniform barriers through chemical curing processes, offering enhanced aesthetic properties like glossiness and hydrophobic characteristics. While coatings provide chemical resistance and surface enhancement, they lack the physical shock-absorption capabilities inherent in PPF technologies. The application method differs significantly: coatings require meticulous surface preparation and precise environmental conditions during installation, whereas PPF can be more flexibly applied across varied workshop environments.

Pro Tip: Evaluate each vehicle’s specific protection requirements by considering usage patterns, environmental exposure, and client expectations before selecting between PPF and coating technologies.

Performance, Durability, and Maintenance Requirements

In the automotive protection landscape, performance and durability represent critical benchmarks for workshops selecting between Paint Protection Film (PPF) and traditional coating systems. Protective technologies vary significantly in their ability to withstand environmental challenges and mechanical stress, making careful selection paramount for long-term vehicle preservation.

PPF demonstrates exceptional durability through its innovative molecular composition, offering robust protection against stone chips, scratches, and ultraviolet radiation. The film’s self-healing properties enable minor surface damages to automatically repair, reducing maintenance interventions and extending the protective layer’s effective lifespan. Thickness variations and high-quality adhesive systems contribute to PPF’s resilience, with premium installations potentially protecting vehicle surfaces for several years under diverse environmental conditions.

Traditional coating systems require more frequent maintenance and inspection protocols to sustain their protective capabilities. Unlike PPF’s relatively passive maintenance approach, coatings demand periodic professional assessment, cleaning, and occasional reapplication to maintain their chemical resistance and aesthetic properties. Environmental factors such as temperature fluctuations, chemical exposure, and mechanical stress significantly impact coating performance, necessitating a more proactive maintenance strategy for workshops committed to delivering consistent vehicle protection.

Pro Tip: Develop a comprehensive maintenance tracking system that documents each vehicle’s protection method, installation date, and environmental exposure to optimise long-term protective performance.

Cost, Efficiency, and Choosing the Right Solution

Workshop managers must conduct meticulous assessments when selecting between Paint Protection Film (PPF) and traditional coating technologies, carefully weighing cost and protective performance against specific operational requirements. The financial implications extend far beyond initial material expenses, encompassing long-term maintenance, labour complexity, and potential value generation for clients.

PPF represents a premium protection strategy characterised by higher upfront investment but substantial long-term benefits. While initial installation costs are significantly higher compared to standard coatings, PPF delivers superior durability, reduced maintenance frequency, and enhanced vehicle preservation. Professional workshops can justify the elevated pricing by highlighting the film’s advanced self-healing properties, comprehensive physical protection, and extended service intervals that ultimately provide greater client satisfaction and potential repeat business.

Traditional coating systems offer more economical entry points for workshops seeking versatile protection solutions. These technologies excel in scenarios requiring aesthetic enhancement, mild chemical resistance, and budget-conscious approaches. The selection process demands nuanced evaluation of vehicle type, client expectations, environmental exposure, and specific protective requirements. Performance vehicles or luxury automotive segments might warrant PPF’s comprehensive protection, whereas standard commuter vehicles could benefit sufficiently from more cost-effective coating technologies.

Pro Tip: Develop a comparative pricing model that transparently demonstrates the long-term value proposition of different protection technologies to help clients make informed decisions.

Find the Perfect Fit for Your Workshop with AEONCUT Cutting Solutions

Choosing between coating and Paint Protection Film (PPF) for your workshop can feel overwhelming. This article highlights key challenges such as balancing physical impact resistance, maintenance demands, and cost efficiency. When your goal is precision and high-quality PPF installation, reducing material waste and ensuring perfect fit are critical to meeting client expectations and boosting workshop efficiency.

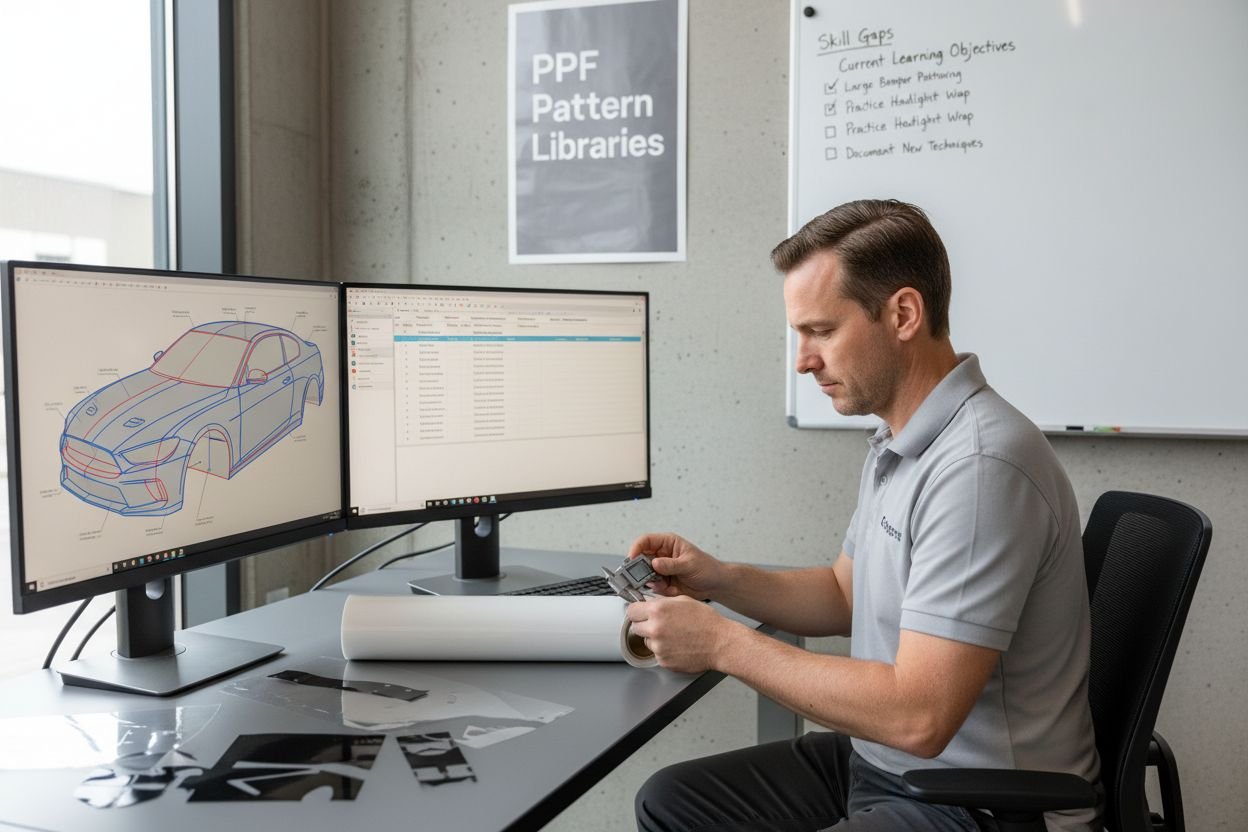

AEONCUT offers cutting-edge PPF software – AEONCUT PPF Pre-cut Cutting software designed to simplify and optimise your PPF application process. With extensive pattern libraries and AI-driven auto-nesting, you can create accurate, custom pre-cut patterns that save time and minimise errors. This technology directly tackles the installation and durability considerations discussed in the article and empowers professionals to deliver superior paint protection results.

Elevate your workshop’s PPF capabilities today by exploring our Paint Protection Film – AEONCUT PPF Pre-cut Cutting software collection and discover subscription plans tailored to professional needs. Visit aeoncutsw.com now to transform your coating or PPF services with smart, precise, and efficient cutting software. Don’t wait to offer your clients the premium protection they expect while maximising your operational success.

Frequently Asked Questions

What is the difference between Paint Protection Film (PPF) and automotive coatings?

Paint Protection Film (PPF) is a transparent, self-healing layer of thermoplastic polyurethane that protects against physical damage, while automotive coatings are liquid-applied treatments that bond with the paint to enhance gloss and provide moderate chemical protection.

How long does Paint Protection Film (PPF) typically last compared to automotive coatings?

PPF can last between 5 to 10 years, depending on the quality, while traditional automotive coatings usually last around 2 to 5 years with proper care.

Does Paint Protection Film (PPF) have self-healing properties?

Yes, many modern Paint Protection Films feature self-healing topcoats that can automatically repair minor scratches, while standard automotive coatings do not have this capability.

What factors should I consider when choosing between PPF and coatings for vehicle protection?

Consider the vehicle’s usage conditions, the level of protection required, client expectations, and budget constraints. Performance vehicles may benefit more from PPF, while standard cars might be well-served by coatings.

Recommended

- PPF Versus Ceramic Coating: Best Choice for Automotive Pros 2025 – AEONCUT PPF Pre-cut Cutting software

- Matte PPF vs Gloss PPF: Professional Comparison 2025 – AEONCUT PPF Pre-cut Cutting software

- Matte PPF vs Gloss PPF: Professional Comparison 2025 – AEONCUT PPF Pre-cut Cutting software

- Matte PPF vs Gloss PPF: Professional Comparison 2025 – AEONCUT PPF Pre-cut Cutting software

- Protecting Your Space with PVC Hygienic Wall Protection