Building a great PPF pattern library can make or break your success as a professional installer. Some experts estimate that even a 1mm mistake in a digital template can completely ruin a full vehicle wrap. Most people think investing in top-end film or fancy tools is the magic ticket. The reality is that your skill, precision and ability to adapt patterns matter far more than expensive gadgets ever could.

Table of Contents

- Step 1: Assess Current PPF Knowledge And Skills

- Step 2: Identify Essential Components Of PPF Pattern Libraries

- Step 3: Gather Required Tools And Resources For Implementation

- Step 4: Implement PPF Patterns In Real-World Scenarios

- Step 5: Evaluate Results And Adjust Patterns Accordingly

Quick Summary

| Key Point | Explanation |

|---|---|

| 1. Assess Your Current Skills | Evaluate your knowledge of PPF materials and installation techniques to identify improvement areas. |

| 2. Map Essential Components | Create a structured digital pattern library with precise vehicle data and measurements for successful installations. |

| 3. Invest in Quality Tools | Acquire professional-grade hardware and software to ensure accurate pattern creation and efficient installations. |

| 4. Execute Thoroughly | Maintain clean surfaces and meticulous application techniques to achieve optimal film adhesion and aesthetics. |

| 5. Continuously Evaluate Performance | Regularly assess pattern effectiveness, document outcomes, and make iterative improvements to enhance your library. |

Step 1: Assess Current PPF Knowledge and Skills

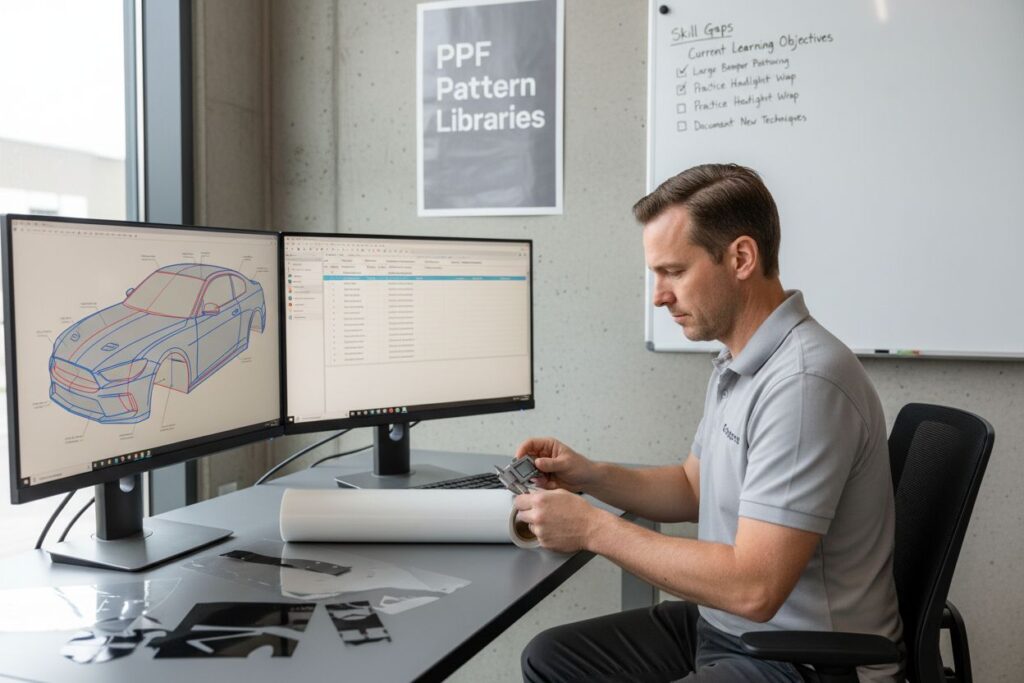

Successful PPF pattern library development begins with a comprehensive assessment of your current knowledge and skill base. This critical first step determines the foundation from which your pattern libraries will evolve, helping you identify precise gaps and opportunities for improvement.

Professional PPF installers must conduct a thorough self-evaluation across multiple dimensions. Start by examining your technical understanding of paint protection film materials, including polymer compositions, adhesive technologies, and film thickness variations. Consider your practical installation experience and document specific areas where your skills might need refinement. Industry expertise requires continuous learning and honest self-assessment.

To effectively map your current capabilities, create a structured skills inventory that covers key competencies. Evaluate your proficiency in surface preparation techniques, film cutting precision, application methods, and pattern recognition. Pay special attention to your ability to work with different vehicle models and surface complexities. Learn more about professional PPF skill development to understand how comprehensive knowledge impacts pattern library creation.

Critical skill assessment areas include:

- Technical knowledge of PPF materials

- Pattern cutting and template creation accuracy

- Understanding of vehicle surface geometries

- Film application techniques

- Problem-solving capabilities during installation

Verification of your skill level involves multiple approaches. Consider seeking peer reviews, participating in professional workshops, or obtaining certification from recognised industry training programmes. These external validations provide objective measurements of your current expertise and highlight potential areas for targeted improvement.

Successful assessment means developing a clear, actionable roadmap for skill enhancement. By understanding your current capabilities, you can strategically invest in training, technology, and resources that will elevate your PPF pattern library development process.

Step 2: Identify Essential Components of PPF Pattern Libraries

Building a robust PPF pattern library requires strategic understanding of its core components and architectural design. This step transforms theoretical knowledge into a structured, functional system that supports precise vehicle protection film installations across diverse automotive models.

The foundation of an exceptional pattern library lies in comprehensive vehicle data mapping. Comprehensive digital templates become the backbone of your pattern collection, requiring meticulous attention to vehicle make, model, year, and specific body panel geometries. Professional installers must develop a systematic approach to capturing intricate surface details, understanding that even millimetre variations can significantly impact film application precision.

Explore advanced pattern creation techniques to understand the nuanced process of developing high-quality digital templates. Your pattern library should incorporate multiple critical elements that ensure versatility and accuracy:

- Precise vehicle panel measurements

- High-resolution digital scans

- Comprehensive edge detection algorithms

- Material thickness compensation parameters

- Surface curvature calculations

Successful pattern library development demands rigorous documentation and standardisation. Implement a consistent naming convention for your digital templates, enabling quick retrieval and seamless integration across different installation projects. Consider developing metadata tags that capture essential information about each pattern, including vehicle specifications, recommended film types, and unique installation notes.

Verification of your pattern library involves multiple validation stages. Test your digital templates against physical vehicle models, comparing generated patterns with actual surface requirements. Pay special attention to complex areas like curved panels, wheel arches, and intricate body lines.

Continuous refinement separates exceptional pattern libraries from basic collections, making iterative improvement a crucial aspect of your development process.

By systematically identifying and documenting essential components, you create a dynamic, adaptable PPF pattern library that serves as a powerful resource for professional installers.

Step 3: Gather Required Tools and Resources for Implementation

Successful PPF pattern library implementation demands a strategic approach to tool and resource selection. This critical step transforms theoretical knowledge into practical capabilities, ensuring your workshop is equipped to handle complex vehicle protection film projects with precision and efficiency.

Professional-grade digital infrastructure forms the cornerstone of effective PPF pattern library development. Invest in high-performance computing systems with substantial graphics processing capabilities, enabling seamless handling of intricate digital templates. Your primary workstation should feature robust processors, minimum 32GB RAM, and dedicated graphics cards capable of rendering complex vehicle surface geometries with exceptional detail.

Discover professional software solutions for PPF pattern management to understand the technological ecosystem supporting modern pattern libraries. Digital cutting software represents a critical resource, requiring comprehensive features like auto-nesting, precision measurement tools, and cloud-based pattern synchronisation.

Critical hardware and software resources include:

- High-resolution digital plotter or cutting machine

- Professional design and pattern creation software

- Calibrated measuring tools and digital calipers

- Cloud storage systems for pattern archival

- Colour-accurate display monitors

Material selection represents another crucial dimension of implementation preparedness. Choose paint protection films from reputable manufacturers that offer consistent quality and predictable performance. Evaluate film characteristics such as thickness, flexibility, self-healing properties, and UV resistance. Maintain an inventory of film samples representing various vehicle makes and models, enabling rapid prototyping and template validation.

Establish robust backup and redundancy systems to protect your developing pattern library. Implement multiple storage solutions, including local hard drives, network-attached storage, and secure cloud platforms. Regularly verify data integrity through comprehensive backup protocols, ensuring no valuable pattern information is ever lost.

Successful tool and resource gathering culminates in a comprehensive workshop ecosystem ready to support advanced PPF pattern library development.

Below is a table summarising the essential tools, software, and materials required for successful PPF pattern library implementation, as outlined in Step 3.

| Resource | Specification/Feature | Purpose |

|---|---|---|

| High-performance computing workstation | Robust processors, minimum 32GB RAM, dedicated graphics card | Handles intricate digital templates |

| Digital plotter or cutting machine | High-resolution capability | Precision pattern cutting |

| Design and pattern creation software | Auto-nesting, measurement tools, cloud sync | Digital pattern development and management |

| Calibrated measuring tools/digital callipers | High precision | Accurate vehicle measurements |

| Cloud storage and backup systems | Redundancy with local/cloud/hard drives | Secure archival of pattern data |

| Colour-accurate display monitors | High colour fidelity | Accurate pattern visualisation |

| Professional PPF films | Consistent thickness, flexibility, UV resistance | Reliable and durable installations |

Step 4: Implement PPF Patterns in Real-World Scenarios

Transitioning from digital templates to actual vehicle protection film application requires meticulous execution and strategic implementation. This pivotal step bridges theoretical design with practical installation, transforming carefully crafted pattern libraries into precise, professional results.

Surface preparation becomes the foundation of successful PPF implementation. Professional installers must create an immaculate environment, ensuring vehicle surfaces are completely free from contaminants, oils, and microscopic debris. Utilise professional-grade cleaning solutions and lint-free microfibre cloths to achieve a pristine surface that enables optimal film adhesion. Temperature and humidity control within your workspace significantly impacts installation quality, with ideal conditions typically ranging between 20-25 degrees Celsius and 40-50% relative humidity.

Explore advanced PPF application techniques to understand the nuanced process of translating digital patterns into flawless physical installations. When applying your meticulously developed patterns, follow a systematic approach that prioritises precision and consistency.

Critical implementation steps include:

- Careful pattern alignment verification

- Gradual film application using professional squeegee techniques

- Minimising air bubble formation

- Managing film tension and stretching

- Precise edge trimming and sealing

According to automotive engineering research, successful PPF implementation requires understanding complex interactions between film materials, vehicle surfaces, and application techniques. Professional installers must develop a keen eye for detail, recognising subtle variations in surface geometry that might impact pattern performance.

Documentation represents a crucial aspect of real-world pattern implementation. Maintain comprehensive installation records for each vehicle, capturing specific challenges, material performance, and any necessary pattern adjustments. These insights become invaluable for continuous library refinement, enabling iterative improvements in your digital templates.

Verification of successful implementation involves rigorous post-installation inspection. Carefully examine film edges, surface coverage, and overall aesthetic quality. Look for uniform adhesion, absence of air bubbles, and seamless integration with vehicle contours. By treating each installation as a learning opportunity, you transform practical experience into enhanced pattern library sophistication.

Step 5: Evaluate Results and Adjust Patterns Accordingly

Evaluating PPF pattern performance represents a critical phase in developing a robust, adaptive digital library. This systematic assessment transforms installation experiences into actionable insights, enabling continuous improvement of your pattern collection through meticulous analysis and strategic refinement.

Comprehensive performance evaluation requires a multifaceted approach that goes beyond superficial visual inspection. Professional installers must develop a structured methodology for capturing detailed installation feedback, tracking pattern accuracy, material compatibility, and long-term durability. Implement a rigorous documentation system that records specific details about each installation, including vehicle make, model, environmental conditions, and any challenges encountered during application.

Discover professional pattern optimization techniques to understand advanced methods for pattern library enhancement. Create a comprehensive evaluation framework that captures both immediate installation outcomes and long-term performance metrics.

Critical evaluation parameters include:

Precise edge alignment accuracy

Material conformity to vehicle contours

Film durability under various environmental conditions

Self-healing properties performance

UV resistance and colour stability

According to automotive engineering research, effective pattern evaluation involves systematic tracking of installation performance across multiple dimensions. Develop a scoring system that assigns quantitative values to different aspects of pattern performance, enabling objective comparison and targeted improvements.

Digital archiving becomes a critical component of the evaluation process. Maintain a comprehensive digital repository of installation photographs, performance notes, and client feedback. Leverage advanced image analysis techniques to identify subtle pattern variations that might require refinement. Regularly cross-reference your pattern library with the latest vehicle models, ensuring continuous adaptation to evolving automotive design trends.

Successful pattern library evaluation culminates in a dynamic, self-improving system. By treating each installation as a learning opportunity, professional installers transform practical experience into increasingly sophisticated digital templates.

The goal is not perfection, but continuous, incremental improvement that reflects the latest industry technologies and installation techniques.

The goal is not perfection, but continuous, incremental improvement that reflects the latest industry technologies and installation techniques.

Transform Your PPF Pattern Library with AEONCUT Precision

Building and evolving a high-performance PPF pattern library demands more than technical skill and theory. The journey outlined in “PPF Pattern Libraries: What’s Inside and How They Evolve” speaks directly to the challenges you face. Pain points such as limited template accuracy, slow pattern updates, and inefficient installation workflows are all too common. When every millimetre matters, relying on yesterday’s methods holds you back. What if your pattern library could evolve as fast as you do and keep you ahead of the curve?

See how PPF precut pattern technology can streamline your next project with the AEONCUT software suite. Enjoy cloud-based pattern updates, industry-leading accuracy, and access to one of the most extensive digital libraries available. Take the next step today at aeoncutsw.com and turn every installation into a benchmark of professional excellence.

Frequently Asked Questions

What is a PPF pattern library?

A PPF pattern library is a collection of digital templates designed for the precise application of paint protection film on various vehicle models. It includes detailed measurements and design elements that ensure optimal film fitting and protection.

How do I assess my skills for PPF pattern library development?

To assess your skills, conduct a self-evaluation that examines your technical understanding of PPF materials, installation experience, and surface preparation techniques. Creating a structured skills inventory can help identify areas for improvement.

What are the essential components of a successful PPF pattern library?

Essential components include comprehensive vehicle data mapping, precise panel measurements, high-resolution digital scans, and detailed installation notes. It also requires a systematic approach to file naming and metadata tagging for easy retrieval.

How can I evaluate the performance of my PPF patterns?

You can evaluate performance by tracking installation accuracy, assessing material compatibility, and documenting long-term durability. Maintaining a detailed repository of installation feedback and adjusting patterns based on real-world outcomes is crucial for continuous improvement.

Recommended

- Aeoncut yordamida maxsus PPF naqshlarini qanday yaratish mumkin: bosqichma-bosqich qo’llanma – AEONCUT PPF oldindan kesilgan kesish dasturi

- How to Create Custom PPF Patterns Using Aeoncut: Step-by-Step Guide – AEONCUT PPF Pre-cut Cutting software

- How to Create Custom PPF Patterns Using Aeoncut: Step-by-Step Guide – AEONCUT PPF Pre-cut Cutting software

- Como crear patróns PPF personalizados con Aeoncut: guía paso a paso: software de corte precortado PPF AEONCUT