PPF and tint cutting software is changing how vehicle specialists work, shaping everything from workflow to profit margins. Even seasoned installers might be surprised that with modern platforms, advanced cutting software can reduce material waste by up to 10%, delivering real savings and sharper results. Many assume the cutting plotter is the key tool, but today, it is the software that decides just how precise and profitable each job will become.

Table of Contents

- Essential Features In PPF And Tint Cutting Software

- Comparing The Top 5 Software Solutions For 2025

- Choosing The Right Software For Your Business Needs

- Expert Tips To Maximise Software Efficiency

Quick Summary

| Takeaway | Explanation |

|---|---|

| Comprehensive Pattern Libraries Are Essential | The most effective PPF and tint cutting software features extensive and updated vehicle databases that provide accurate templates for various makes and models, reducing material waste and ensuring precise film application. |

| Integration and Compatibility Matter | Professionals should select software that seamlessly integrates with various hardware and operating systems to maintain workflow efficiency and support diverse installation setups. |

| Evaluate Based on Specific Business Needs | When choosing software, assess your business scale, team size, and technical infrastructure to ensure the selected solution meets operational demands and long-term scalability. |

| Training Fosters Efficiency | Continuous professional development through certification programs and hands-on workshops is crucial for installers to maximise software capabilities and stay updated with cutting techniques. |

| Adopt Workflow Optimization Techniques | Implementing strategies such as template standardisation and batch processing can significantly enhance efficiency, reduce film waste, and improve overall operational performance. |

Essential Features in PPF and Tint Cutting Software

Professional PPF and tint cutting software has become a game-changing tool for automotive customization specialists. These advanced solutions transform how installers approach vehicle protection and aesthetic modifications. Understanding the critical features that distinguish top-tier cutting software is paramount for professionals seeking precision and efficiency.

Pattern Library and Vehicle Database Sophistication

The backbone of exceptional PPF and tint cutting software lies in its comprehensive pattern library. Modern software solutions offer expansive databases containing pre-configured templates for thousands of vehicle makes and models. According to Media Tech Insights, precision and accuracy are fundamental requirements for professional installers. High-quality software provides verified patterns that minimize material waste and ensure perfect film application.

Top-tier software platforms continuously update their vehicle databases, recognizing that automotive designs evolve rapidly. Professionals need access to the most recent vehicle specifications to guarantee exact pattern matching. AEONCUT PPF Pre-cut Cutting software emphasizes the importance of maintaining an up-to-date pattern library that covers global automotive manufacturers.

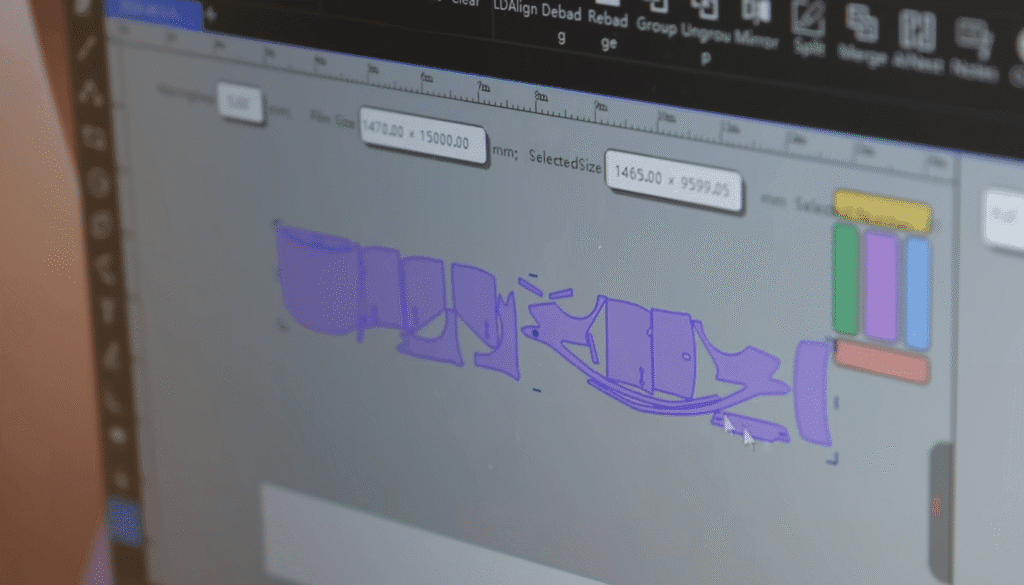

Advanced Customization and Editing Tools

Beyond pre-existing patterns, professional cutting software must offer robust customization capabilities. Installers frequently encounter unique vehicles or specific client requirements that demand precise adjustments. Advanced editing tools allow professionals to modify existing templates, create custom patterns, and adapt designs to specific vehicle modifications.

Leading software solutions like SunTek provide user-friendly interfaces with powerful editing functionalities. These tools enable professionals to:

- Precise Scaling: Adjust patterns with millimeter-level accuracy

- Custom Trimming: Create unique edges and contours for complex installations

- Digital Nesting: Optimize material usage by intelligent pattern placement

Compatibility and Integration Capabilities

Modern PPF and tint cutting software must seamlessly integrate with various hardware and operating systems. Professionals require solutions that work across different plotter models, computer platforms, and cutting machines. According to LLumar, software compatibility is crucial for maintaining workflow efficiency and supporting diverse professional setups.

Key integration features include:

- Cross-platform support (Windows and macOS)

- Multiple plotter and cutting machine compatibility

- Cloud-based updates and pattern synchronization

- Intuitive user interfaces that minimize training requirements

Choosing the right PPF and tint cutting software involves carefully evaluating these essential features. Professionals must prioritize solutions offering comprehensive pattern libraries, advanced customization tools, and robust hardware integration to maximize their installation precision and operational efficiency.

To clarify the primary features for evaluating PPF and tint cutting software, the following table summarises the essential factors mentioned above:

| Essential Feature | Why It Matters | Example Capabilities |

|---|---|---|

| Pattern Library Depth | Ensures accurate fit for various vehicles | Verified, updated templates |

| Customisation & Editing Tools | Allows adjustments for unique jobs | Precise scaling, custom trimming, digital nesting |

| Integration & Compatibility | Smooth workflow across devices/plotters | Windows/macOS support, cloud sync, multi-machine |

| Update Frequency | Keeps patterns and features current | Regular pattern & technology enhancements |

| Usability & Training | Minimises training time, boosts efficiency | Intuitive UI, educational resources |

Comparing the Top 5 Software Solutions for 2025

Professional PPF and tint cutting software has rapidly evolved, offering increasingly sophisticated solutions for automotive customization specialists. As we explore the top 5 software solutions for 2025, professionals can gain insights into the most advanced tools transforming the industry.

Performance and Technological Innovation

The competitive landscape of PPF cutting software is defined by continuous technological advancement. According to Media Tech Insights, the most effective solutions distinguish themselves through precision, user experience, and comprehensive feature sets. AEONCUT software recognizes that professionals require more than basic cutting capabilities.

Top software solutions are evaluated across multiple critical dimensions:

- Pattern Accuracy: Millimeter-precise vehicle-specific templates

- Customization Depth: Advanced editing and modification capabilities

- Integration Flexibility: Compatibility with diverse hardware and operating systems

- Update Frequency: Regular database and feature improvements

Comparative Analysis of Leading Solutions

Comparing top PPF and tint cutting software requires a nuanced approach. Yink Global provides insights into the most prominent solutions in the market, highlighting key differentiators.

The top 5 software solutions for 2025 include:

- AEONCUT Pro: Known for its comprehensive pattern library and AI-driven auto-nesting technology

- DigiCut Advanced: Offers exceptional cross-platform compatibility and real-time pattern editing

- SunTek CutMaster: Provides an extensive global vehicle database with user-friendly interface

- XPEL Design Access: Features sophisticated customization tools and cloud-based synchronization

- Kavaca Smart Cut: Specializes in rapid pattern generation and material optimization

To assist in quickly comparing the strengths of the top 5 PPF and tint cutting software for 2025, this table highlights their distinguishing features as noted in the article:

| Software Solution | Notable Feature(s) | Standout Technology |

|---|---|---|

| AEONCUT | Comprehensive pattern library | AI-driven auto-nesting |

| DigiCut | Exceptional cross-platform compatibility | Real-time pattern editing |

| SunTek Core | Extensive global vehicle database | User-friendly interface |

| XPEL Dap | Sophisticated customisation, cloud sync | Advanced editing tools |

| Kavaca Smart Cut | Rapid pattern generation, material optimisation | Intelligent material usage |

Cost-Effectiveness and Professional Value

Professionals must evaluate software solutions beyond their immediate features. According to SunTek, the most valuable software solutions offer a balance between technological capabilities and return on investment.

Key considerations for software selection include:

- Subscription pricing models

- Training and support resources

- Integration costs with existing equipment

- Potential productivity gains

- Long-term scalability

The ideal PPF and tint cutting software solution combines technological sophistication with practical usability. Professionals should conduct thorough evaluations, potentially utilizing trial periods and requesting detailed demonstrations to understand each platform’s unique strengths and potential limitations.

Choosing the Right Software for Your Business Needs

Selecting the appropriate PPF and tint cutting software represents a critical strategic decision for automotive customization businesses. The right software can dramatically enhance operational efficiency, reduce material waste, and ultimately improve profitability.

Assessing Your Business Scale and Requirements

Every automotive customization business operates with unique workflow dynamics and technological infrastructure. Induction Film highlights that software selection must align precisely with specific business needs. Professional installers must conduct a comprehensive internal assessment focusing on several key parameters:

- Installation Volume: Determine the number of vehicles processed monthly

- Team Size: Evaluate software user capacity and multi-user functionality

- Technical Infrastructure: Analyze existing hardware and computer systems

- Budget Constraints: Consider initial investment and ongoing subscription costs

Professionals should recognize that one-size-fits-all solutions rarely deliver optimal results. AEONCUT PPF Pre-cut Cutting software emphasizes the importance of matching software capabilities with specific business requirements.

Comprehensive Feature Evaluation

Beyond basic cutting capabilities, modern PPF software demands a holistic feature set. According to Protector Automotive, top-tier solutions integrate advanced technologies that transform operational workflows.

Critical features to evaluate include:

- Pattern Database Depth: Comprehensive vehicle template libraries

- Update Frequency: Regular pattern and technology enhancements

- Integration Capabilities: Compatibility with existing plotters and systems

- Support and Training: Robust customer service and educational resources

- Customization Potential: Ability to create unique patterns and modifications

Financial and Operational Considerations

UPPF UltraFilmCut demonstrates that advanced cutting software can reduce material waste by up to 10%, presenting significant long-term financial benefits. Professionals must evaluate software not just as a technological tool, but as a strategic investment.

Key financial considerations include:

- Potential productivity gains

- Reduced material waste percentages

- Training and implementation costs

- Subscription model flexibility

- Potential return on investment timeframe

Successful software selection requires a balanced approach. Businesses should leverage trial periods, request comprehensive demonstrations, and consult with industry peers. The goal is finding a solution that not only meets current operational needs but also provides scalability for future growth and technological advancements.

Ultimately, the right PPF and tint cutting software acts as a strategic partner, enabling businesses to enhance precision, efficiency, and overall professional capabilities in an increasingly competitive automotive customization market.

Expert Tips to Maximise Software Efficiency

Maximizing the potential of PPF and tint cutting software requires more than just technical knowledge. Professional installers must develop strategic approaches to leverage these advanced technological tools effectively and efficiently.

Training and Skill Development

Professional development forms the cornerstone of software efficiency. According to Le Jeune Ceramic Coating, certification programs and hands-on workshops are critical for mastering cutting techniques. These educational opportunities provide installers with insights into the nuanced capabilities of modern cutting software.

Key training strategies include:

- Manufacturer Certification: Pursuing specialized training from software providers

- Continuous Learning: Attending webinars and online workshops

- Peer Networking: Participating in professional forums and discussion groups

- Hands-on Practice: Dedicating time to exploring software features and capabilities

Workflow Optimization Techniques

Efficient software utilization demands a systematic approach to workflow management. Media Tech Insights emphasizes the importance of developing streamlined processes that minimize time and material waste.

Professionals can optimize their workflow through:

- Template Standardization: Creating and saving custom templates for recurring vehicle models

- Batch Processing: Utilizing software features for simultaneous pattern generation

- Material Optimization: Leveraging auto-nesting technologies to reduce film waste

- Regular Software Updates: Ensuring access to the latest features and pattern libraries

Performance Monitoring and Continuous Improvement

Technological mastery requires ongoing assessment and refinement. Successful installers treat their software as a dynamic tool that demands continuous attention and strategic optimization.

Performance improvement strategies include:

- Detailed Tracking: Monitoring time spent on each installation

- Error Analysis: Identifying and addressing pattern cutting inefficiencies

- Client Feedback Integration: Using customer insights to refine cutting techniques

- Hardware Compatibility: Regularly assessing and updating peripheral equipment

Professionals who approach PPF and tint cutting software as more than just a technical tool will transform their operational capabilities. By investing in training, optimizing workflows, and maintaining a commitment to continuous improvement, installers can unlock the full potential of these advanced technological solutions.

The journey to software efficiency is ongoing. It requires dedication, curiosity, and a willingness to adapt to emerging technologies and techniques in the rapidly evolving automotive customization industry.

Frequently Asked Questions

What features should I look for in PPF and tint cutting software?

Look for comprehensive pattern libraries, advanced customisation and editing tools, compatibility with various plotters and hardware, and regular updates to ensure accuracy and efficiency in your installations.

How can PPF and tint cutting software improve my business?

By using advanced cutting software, you can reduce material waste by up to 10%, enhance precision in installations, streamline workflow, and ultimately improve profitability in your automotive customisation business.

Which PPF and tint cutting software solutions are the best for 2025?

The top five solutions for 2025 include AEONCUT Pro, DigiCut Advanced, SunTek CutMaster, XPEL Design Access, and Kavaca Smart Cut, each known for their unique features and technological innovations.

How do I choose the right cutting software for my needs?

Assess your business size, technical requirements, and budget constraints. Consider factors such as installation volume, team size, and existing hardware compatibility when evaluating different software options.

Ready to Transform Your PPF and Tint Workflow?

Have you ever felt frustrated by wasted material and inaccurate cuts during installations? As highlighted in “Top 5 PPF and Tint Cutting Software for Professionals 2025”, precision and efficiency are not just dreams for automotive specialists. They are crucial needs when every millimetre and minute counts. Many professionals struggle with outdated templates, limited pattern libraries, or software that cannot evolve as quickly as vehicle designs change. If you are searching for a smarter solution to remove these barriers and enhance accuracy, explore our extensive PPF precut pattern resources, crafted for your real-world challenges.

Thousands of professionals choose AEONCUT because it gives access to an AI-powered platform that updates instantly, featuring unlimited vehicle patterns and full support. Do not let another job go by with wasted time or unnecessary costs. Visit AEONCUT today to unlock efficient, future-proof PPF and tint cutting and see how your business can lead the market.

Recommended

- PPF Cutting Software: Essential Guide for Installers 2025 – AEONCUT PPF Pre-cut Cutting software

- What is Window Tint? Essential Guide for Tinting Pros 2025 – AEONCUT PPF Pre-cut Cutting software

- Types of Window Tint: Guide for Installers and Dealers 2025 – AEONCUT PPF Pre-cut Cutting software

- Home – AEONCUT PPF Pre-cut Cutting software