Clear Bra and PPF might sound identical on paper and both promise top-tier protection for your car’s paintwork. Yet, did you know that full PPF can cover up to 100 percent of a vehicle’s exterior while Clear Bra typically only shields the front 30 percent? Most professionals assume it comes down to cost or preference but the true advantage lies in how each method transforms both installation complexity and long-term durability. The real decision is anything but straightforward.

Table of Contents

- Defining Clear Bra And PPF For Pros

- Installation Methods And Challenges

- Performance, Durability, And Maintenance

- How To Choose: Clear Bra Or PPF In 2025?

Quick Summary

| Takeaway | Explanation |

|---|---|

| Clear Bra offers targeted protection. | Clear Bra focuses on high-impact areas like the hood and front bumper, making it ideal for concentrated defence against road debris. |

| Full PPF provides comprehensive coverage. | Full PPF can be applied to the entire vehicle, offering extensive protection in various environmental conditions and for extreme usage. |

| Proper installation is critical for performance. | Meticulous surface preparation and advanced installation techniques ensure optimal film adhesion and longevity, preventing issues like lifting or bubbles. |

| Client needs influence protection choice. | Factors such as vehicle usage, environmental exposure, and budget should guide the decision between Clear Bra and full PPF. |

| Maintenance ensures long-term film effectiveness. | Regular cleaning, gentle care, and inspections are essential for preserving the protective qualities of PPF and Clear Bra over time. |

Defining Clear Bra and PPF for Pros

Professional detailers and automotive protection specialists encounter two closely related yet distinct protective film technologies: Clear Bra and Paint Protection Film (PPF). Understanding the nuanced differences between these solutions is crucial for delivering exceptional vehicle protection services.

The Fundamental Protection Concept

Paint Protection Film represents a sophisticated automotive preservation technology designed to shield vehicle surfaces from environmental damage. Research from automotive protection experts reveals PPF is a thermoplastic urethane film engineered to protect painted surfaces against stone chips, bug splatters, and minor abrasions. Professional installers recognize PPF as an OEM-approved solution that extends beyond traditional automotive applications, finding utility in protecting surfaces ranging from motorcycles to electronic screens.

The term “Clear Bra” often creates confusion among professionals, as it essentially describes a specific application of PPF. Automotive protection specialists define Clear Bra as a strategic, partial PPF installation typically focused on high-impact areas like the hood, fenders, side mirrors, and front bumper. This targeted approach provides concentrated protection where vehicles experience the most potential damage during regular driving conditions.

Strategic Application Differences

While Clear Bra and PPF share fundamental protective characteristics, their application strategies differ significantly. Clear Bra represents a more focused protective approach, concentrating on the vehicle’s most vulnerable front-facing surfaces. Professional automotive protection resources highlight that Clear Bra installations typically cover the front end, offering a precise shield against road debris, stone chips, and environmental contaminants.

Paint Protection Film, conversely, offers more comprehensive coverage options. Professional installers can apply PPF to entire vehicle surfaces, providing holistic protection beyond the front-facing areas. This flexibility allows detailing professionals to customize protection based on client needs, vehicle usage, and specific environmental challenges.

For professionals seeking advanced pattern cutting solutions that enhance PPF installation precision, our guide on professional PPF techniques offers comprehensive insights into modern application methodologies. Understanding these distinctions empowers automotive protection specialists to recommend the most appropriate solution for each unique vehicle protection scenario.

To help professionals clearly compare the defining features and application areas of Clear Bra and full PPF, the following table organises key differences discussed in this section.

| Feature/Aspect | Clear Bra (Partial PPF) | Full PPF (Comprehensive) |

|---|---|---|

| Typical Coverage Area | Front 30% (hood, fenders, bumper, mirrors) | Up to 100% (entire vehicle exterior) |

| Protection Focus | High-impact, front-facing zones | All surfaces, including less exposed areas |

| Customisation Level | Moderate (limited to common areas) | Highly customisable |

| Cost Implications | Generally lower | Higher total investment |

| Ideal Client/Use | Budget-conscious, targeted defence | High-value vehicles, harsh environments |

| Material Used | PPF | PPF |

Installation Methods and Challenges

Professional automotive detailers and PPF installers encounter numerous technical challenges when applying paint protection films. The installation process demands precision, technical expertise, and an understanding of advanced material properties to ensure optimal vehicle surface protection.

Professional Preparation and Surface Readiness

Successful PPF installation begins with meticulous surface preparation. Research from automotive protection studies emphasizes that improper application can significantly compromise the film’s protective capabilities. Professional installers must thoroughly clean and decontaminate vehicle surfaces, removing all waxes, oils, and microscopic debris that could interfere with film adhesion.

The preparation process involves multiple critical steps. Professionals use specialized cleaning solutions and techniques to create an immaculate surface. Clay bar treatments, isopropyl alcohol wipedowns, and precise panel cleaning ensure maximum film adhesion and prevent potential issues like air bubbles, lifting edges, or premature film failure.

Advanced Installation Techniques

Patent research on paint protection films reveals the complexity of applying films to vehicles with intricate surface geometries. Professional installers must navigate challenging panel contours, ensuring the film conforms perfectly without wrinkling or delaminating. This requires advanced skills in stretching, positioning, and heat application techniques.

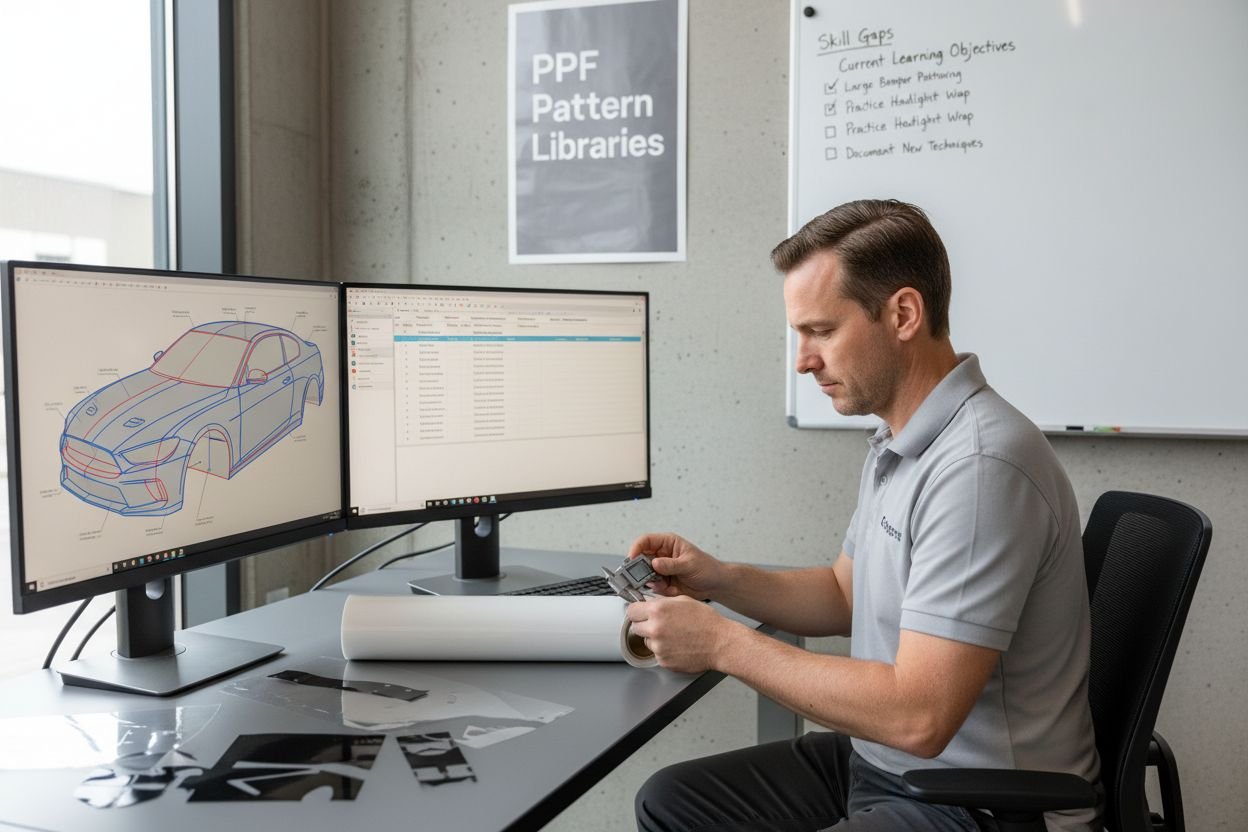

Two primary installation methods dominate professional practice. The first involves pre-cut patterns generated by specialized software, which allows for precise panel coverage with minimal waste. The second method requires bulk film installation, where installers cut the film directly on the vehicle surface. While the latter offers flexibility, it carries significant risks of potential paint damage if not executed with extreme precision.

Technical Challenges and Quality Control

Technical documentation from PPF manufacturers highlights the intricate challenges professionals face during installation. Environmental factors like temperature and humidity can dramatically impact film performance. Installers must work in controlled environments, typically maintaining temperatures between 20-25 degrees Celsius with controlled humidity levels to ensure optimal film adhesion and longevity.

Quality control represents another critical aspect of professional PPF installation. Experienced installers conduct rigorous post-installation inspections, checking for potential issues such as edge lifting, air bubbles, and surface imperfections. Advanced tools and techniques, including specialized lighting and magnification, enable professionals to identify and rectify potential installation defects.

For professionals seeking to enhance their PPF installation precision, our comprehensive guide on professional cutting techniques offers advanced insights into modern application methodologies. Understanding these nuanced installation challenges empowers automotive protection specialists to deliver exceptional vehicle protection services.

Performance, Durability, and Maintenance

Professional automotive protection specialists understand that the true value of Paint Protection Film (PPF) and Clear Bra technologies extends far beyond initial installation. Performance, durability, and maintenance represent critical factors that determine the long-term effectiveness of these protective solutions.

Material Performance and Protection Characteristics

Comprehensive research on automotive protection technologies reveals that modern PPF represents a sophisticated defense mechanism for vehicle surfaces. Professional-grade films offer remarkable protection against environmental challenges, including rock chips, bug splatters, and minor abrasions. The most advanced PPF technologies now incorporate self-healing top coats capable of reforming after minor scratches, maintaining optical clarity for extended periods.

The performance spectrum varies significantly between different PPF grades. High-end films provide exceptional UV resistance, preventing paint oxidation and maintaining the vehicle’s aesthetic appeal. Professional installers recognize that thickness, material composition, and manufacturing quality directly impact the film’s protective capabilities.

Durability and Environmental Resilience

Automotive protection experts highlight the critical differences in PPF performance across diverse environmental conditions. In coastal regions, the film demonstrates remarkable resistance to salt corrosion, while desert environments test the material’s heat and UV resistance. Professional-grade PPF maintains its protective properties across extreme temperature ranges, offering consistent protection in challenging climates.

Durability metrics extend beyond environmental resistance. Professional installers assess film performance through multiple criteria, including:

- Impact Resistance: Ability to absorb rock chips and minor impacts

- Clarity Retention: Maintaining optical transparency over time

- Edge Adhesion: Preventing lifting and peeling

- Flexibility: Conforming to complex vehicle surface geometries

The following table summarises durability and performance criteria for PPF and Clear Bra installations, providing a quick reference for professionals.

| Criteria | Importance | Notes for Professionals |

|---|---|---|

| Impact Resistance | Absorbs stone chips and minor impacts | Essential for protection in high-impact areas |

| Clarity Retention | Maintains optical transparency over time | Important for vehicle aesthetics |

| UV Resistance | Prevents paint oxidation | Key for long-term protection |

| Edge Adhesion | Prevents lifting and peeling | Critical for longevity |

| Flexibility | Conforms to complex vehicle surface geometries | Ensures seamless coverage |

| Environmental Resilience | Withstands salt, heat, and varying climate conditions | Tailor material selection to client’s environment |

Maintenance and Long-Term Care

Maintaining PPF requires a strategic approach that differs from traditional automotive protection methods. Regular cleaning and careful maintenance are essential to preserving the film’s protective qualities. Professional detailers recommend specific cleaning techniques that prevent potential damage while maintaining the film’s integrity.

Environmental factors play a significant role in PPF maintenance. Coastal, desert, and winter conditions each present unique challenges that require tailored maintenance approaches. Our comprehensive guide on professional PPF techniques provides advanced insights into managing these environmental challenges.

Professional installers must educate clients about proper maintenance, emphasizing the importance of:

- Gentle Cleaning: Using pH-neutral cleaning solutions

- Avoiding Harsh Chemicals: Preventing potential film degradation

- Regular Inspections: Identifying and addressing potential issues early

Ultimately, the performance of PPF depends on a combination of professional installation, high-quality materials, and ongoing maintenance. By understanding these critical factors, automotive protection specialists can deliver exceptional long-term vehicle surface protection.

How to Choose: Clear Bra or PPF in 2025?

Professional automotive protection specialists face a critical decision when recommending protective solutions for clients: selecting between Clear Bra and full Paint Protection Film (PPF). Understanding the nuanced differences and specific application scenarios is crucial for making informed recommendations in 2025.

Coverage and Protection Strategy

Automotive protection experts emphasize that the primary distinction between Clear Bra and PPF lies in coverage areas. Clear Bra represents a targeted approach, typically applied to the vehicle’s front-facing surfaces most vulnerable to environmental damage. This strategic partial coverage focuses on high-impact zones like the hood, front fenders, bumper, and side mirrors.

Full PPF, conversely, offers comprehensive vehicle protection. Professional installers can apply the film to entire vehicle surfaces, including doors, roof, rear panels, and even less exposed areas. This approach provides holistic protection against a broader range of environmental challenges, making it ideal for vehicles experiencing more extreme driving conditions or for clients seeking maximum surface preservation.

Client-Specific Considerations

Detailed automotive protection research reveals that choosing between Clear Bra and full PPF depends on multiple client-specific factors. Professional installers must consider:

- Vehicle Usage: Daily commuter vehicles versus weekend luxury cars

- Environmental Exposure: Coastal regions, desert environments, urban landscapes

- Client Budget: Partial protection versus comprehensive coverage

- Vehicle Value: High-end vehicles requiring extensive protection

Budget-conscious clients might prefer Clear Bra for its more targeted and cost-effective approach. Owners of premium vehicles or those frequently driving in challenging environments might opt for full PPF coverage to ensure maximum protection.

Technical Selection Criteria

Comprehensive automotive protection documentation highlights the technical considerations professionals must evaluate. Modern PPF technologies offer varying thicknesses, self-healing capabilities, and UV resistance. Clear Bra installations provide focused protection with potentially lower material costs, while full PPF represents a more comprehensive investment in vehicle preservation.

Professional installers should conduct detailed consultations, assessing:

- **Client driving patterns

- **Typical environmental exposures

- **Long-term vehicle maintenance goals

- **Aesthetic preferences for film visibility

Our comprehensive guide on professional PPF techniques provides advanced insights to help professionals make precise recommendations. The ultimate goal remains delivering tailored protection that meets each client’s unique automotive preservation needs.

By carefully evaluating these multifaceted considerations, automotive protection specialists can confidently recommend the most appropriate protective solution, whether a strategic Clear Bra installation or comprehensive Paint Protection Film coverage.

Frequently Asked Questions

What is the main difference between Clear Bra and Paint Protection Film (PPF)?

The primary difference lies in coverage; Clear Bra typically protects the front 30% of a vehicle, focusing on high-impact areas, while full PPF can cover up to 100% of the vehicle’s exterior for comprehensive protection.

How does the installation process differ between Clear Bra and PPF?

Installation of Clear Bra is generally less complex as it is only applied to specific areas. In contrast, full PPF requires meticulous preparation and more advanced techniques to ensure proper adhesion across the entire vehicle surface.

What factors should be considered when choosing between Clear Bra and PPF?

Considerations include vehicle usage, environmental exposure, budget, and the level of protection desired. High-value vehicles or those used in harsh conditions typically benefit from full PPF coverage, while budget-conscious clients may prefer the targeted protection of Clear Bra.

How do maintenance practices differ for Clear Bra and PPF installations?

Both require regular cleaning and careful maintenance, but PPF may demand more attention due to its extensive coverage. It’s crucial to use pH-neutral cleaning solutions and to inspect the film periodically for issues like lifting or scratching to ensure longevity.

Achieve Flawless PPF and Clear Bra Precision – Let Technology Do the Hard Work

Are you struggling with tedious pattern cutting or worried about the waste and inaccuracies that come with PPF and Clear Bra installations? Detailing professionals like you know that the difference between partial and full vehicle protection comes down to perfect fit and razor-sharp application, as explained in the article above. Imperfect cuts, difficult surface contours, and wasted material can compromise both the appearance and durability of every install. The demand for accuracy and efficiency is greater than ever, and this is exactly where advanced technology gives you the edge.

Experience the future of paint protection by switching to the AEONCUT platform. Our software offers access to a vast library of pre-cut PPF and Clear Bra pattern templates, precise AI-powered customisation, and easy cloud updates. Save valuable time, eliminate guesswork, and impress your clients with a professional finish every time. Explore our subscription options or dive deeper with our tutorials and resources to transform your install process today. For results that keep your customers coming back, visit aeoncutsw.com now and start working smarter with PPF.

Recommended

- Matte PPF vs Gloss PPF: Professional Comparison 2025 – AEONCUT PPF Pre-cut Cutting software

- Matte PPF vs Gloss PPF: Professional Comparison 2025 – AEONCUT PPF Pre-cut Cutting software

- How Does PPF Work? Guide for Car Care Pros 2025 – AEONCUT PPF Pre-cut Cutting software

- PPF Versus Ceramic Coating: Best Choice for Automotive Pros 2025 – AEONCUT PPF Pre-cut Cutting software

1 Comment

Michelle Catapang

This post does a fantastic job demystifying the difference between Paint Protection Film (PPF) and the commonly used term “Clear Bra”, especially for detailing professionals navigating 2025 trends!