Finding the best PPF software in 2025 is no small feat when auto businesses are inundated with flashy features and endless options. Surprise yourself with this. Research shows that advanced AI-driven PPF software can cut pattern preparation time by over

PPF and tint cutting software is changing how vehicle specialists work, shaping everything from workflow to profit margins. Even seasoned installers might be surprised that with modern platforms, advanced cutting software can reduce material waste by up to 10%, delivering

PPF has become the go-to solution for keeping a car’s paintwork pristine and untouched. Some films can now self-heal from scratches and resist temperatures from -40°C right up to 80°C. You might think this sort of defence would dull the

Paint protection film has become essential for keeping vehicles looking flawless and fresh for years. You might assume it is as simple as sticking on some clear plastic and forgetting about it. Yet, studies show that top tier films with

Window tint might look simple, but its hidden science goes much deeper than appearance. Here is the surprise. Some professional window tints can cut energy costs by up to 30 percent and block up to 99 percent of

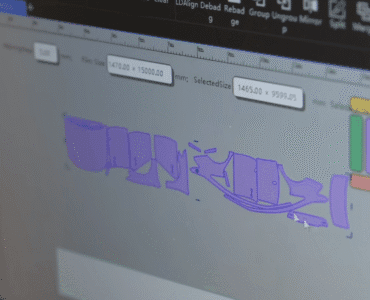

PPF cutting software is rewriting the rules for professional installers, making paint protection film jobs faster and more precise than ever. Here is something that catches everyone’s eye. Advanced software can reduce material waste by up to 30 percent compared